CSST Gas Lines

CSST (Corrugated Stainless Steel Tubing) has become a popular alternative to traditional black iron gas piping due to several key advantages. Here’s why many homeowners, contractors, and inspectors prefer CSST:

1. Faster and Easier Installation

- Fewer Fittings Required – Unlike black iron pipe, which requires multiple joints and fittings to change direction, CSST can be routed in long, continuous runs with fewer connections.

- Flexible Design – CSST can bend around corners and obstacles, reducing the need for elbows and couplings.

- Lightweight – Easier to handle and transport compared to heavy black iron pipes.

2. Reduced Risk of Leaks

- Fewer connections mean fewer potential leak points compared to black iron, which requires threaded joints at every change in direction.

- Continuous runs of CSST lower the chance of improper fittings that could lead to gas leaks.

3. Increased Safety

- Seismic & Vibration Resistance – CSST is flexible and absorbs movement from seismic activity or minor building shifts better than rigid black iron.

- Lightning Protection (When Properly Bonded) – CSST is designed to be bonded to the electrical grounding system, reducing the risk of fire from lightning-induced surges.

4. Durability & Longevity

- Corrosion Resistance – Unlike black iron, which is prone to rust and corrosion over time, CSST’s stainless steel design resists environmental damage.

- Longer Lifespan – CSST typically lasts longer in humid, wet, or corrosive environments where black iron may deteriorate.

5. Lower Labor & Material Costs

- Less Labor-Intensive – Installing black iron pipe requires cutting, threading, and sealing each connection, which takes time. CSST is faster to install, reducing labor costs.

- Fewer Materials Needed – Since CSST requires fewer fittings and shorter install times, material and labor expenses are generally lower.

6. Versatility in Installation

- Can be routed through walls, attics, crawl spaces, and even retrofitted into existing homes more easily than rigid black iron.

- Ideal for both residential and light commercial applications.

When Black Iron Is Still Preferred:

- Outdoor or Exposed Installations – CSST is not designed for direct exposure to physical damage, so black iron is often required for outdoor gas lines or installations where physical protection is necessary.

- High-Pressure Systems – Some high-pressure gas systems may still require black iron due to its strength.

- Local Code Requirements – Some jurisdictions may have restrictions on CSST use or require specific bonding measures.

Why CSST Must Be Bonded

CSST is used for distributing natural gas or propane throughout a home, often running through walls, ceilings, and attics. The main reason it requires bonding is:

Ex. CSST bonding

- Lightning Protection – CSST has a thin-walled design that makes it susceptible to punctures from electrical surges, particularly from lightning strikes. If an unbonded CSST system becomes energized due to a nearby lightning strike, arcing can occur, potentially causing gas leaks and fire hazards.

- Code Requirements – The National Fuel Gas Code (NFPA 54) and International Fuel Gas Code (IFGC) require that CSST be bonded to the electrical grounding system using a minimum of a #6 AWG copper conductor. This directs stray electrical energy safely into the ground rather than allowing it to arc through the tubing.

- Length and Exposure – CSST runs longer distances through the structure, increasing the chance of exposure to electrical events. Since it often passes near metal framing or other conductive materials, the risk of an electrical fault affecting it is higher.

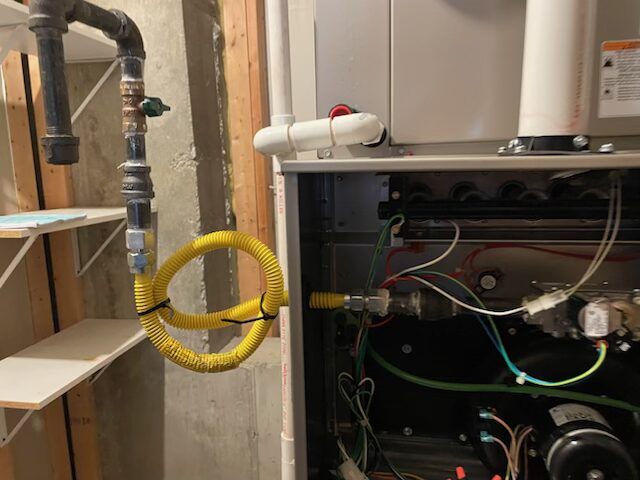

CSST

Why Flexible Appliance Connectors Do Not Require Bonding (FAC)

On the other hand, flexible appliance connectors (e.g., for a furnace, water heater, or stove) do not require bonding because:

- Shorter Length – These connectors are typically only 3 to 6 feet long, significantly reducing the exposure to lightning-induced voltage surges.

- Factory Coatings – Many appliance connectors are coated or designed to minimize electrical conductivity risks.

- Connection to Grounded Appliances – They are typically connected directly to a grounded appliance (e.g., a furnace or water heater, which is often grounded through its electrical system), providing some level of natural grounding.

- Not Routed Through the Structure – Unlike CSST, flexible appliance connectors are not run inside walls or through the home’s framing, so they are less likely to be affected by electrical surges from external sources.

Flexible Appliance Connector

Common Applications:

- Gas Stoves / Ranges – Connects the stove to the home’s gas supply while allowing slight movement when sliding the appliance for cleaning or maintenance.

- Gas Water Heaters – Provides a flexible link between the gas line and the water heater burner system.

- Gas Furnaces – Used to connect furnaces to the gas supply, especially when some movement or vibration is expected.

- Gas Dryers – Allows for easy installation and movement of a gas dryer while preventing stress on the gas line.

- Gas Fireplaces – Used to connect freestanding gas fireplaces or inserts to the home’s gas system.

- Outdoor Grills – Often used for built-in or stationary gas grills connected to a home’s natural gas supply.

- Portable Generators & Heaters – Some permanent or semi-permanent gas-powered generators and space heaters use flexible connectors.

Why Use Flexible Connectors?

- Vibration Resistance – Appliances like dryers and furnaces create slight movement and vibration, and a flexible connector prevents gas line damage.

- Ease of Installation – No need for rigid pipe threading or precise alignment, making installation simpler.

- Allows for Appliance Movement – Appliances like stoves and dryers need to be pulled out for cleaning or repairs, and a flexible connector allows for this without stressing the gas line.

These connectors are not designed for long runs or to pass through walls, floors, or ceilings, which is why CSST is used for whole-house gas distribution, while flexible connectors are used only at the appliance connection point. CSST is bonded to protect against lightning-induced electrical surges, which could puncture the tubing and create a fire risk. Appliance connectors, being shorter and typically grounded through the appliance, do not present the same level of risk and are exempt from bonding requirements.

Choosing the Right Gas Piping for Your Home

Both CSST (Corrugated Stainless Steel Tubing) and flexible gas appliance connectors serve important roles in modern gas piping systems, but they are designed for different applications. CSST provides a flexible, efficient, and corrosion-resistant solution for distributing gas throughout a home, reducing the number of connections and potential leak points. However, because of its susceptibility to electrical surges, proper bonding and grounding are essential to ensure safety.

If you’re unsure about your gas piping system or need an inspection, consulting with a qualified home inspector or licensed gas professional can provide peace of mind and keep your home safe.

On the other hand, flexible gas appliance connectors are ideal for short, localized connections to appliances such as stoves, furnaces, and water heaters. While they allow for easy installation and movement, they are not designed for whole-house gas distribution and do not require bonding like CSST.

When deciding which option is best, it’s crucial to follow local building codes, manufacturer guidelines, and industry best practices to ensure safety and efficiency. Proper installation, inspection, and maintenance of any gas piping system will help protect your home and ensure long-term reliability.